At Triple Arc Welding Solutions Ltd., our work spans a wide range of welding engineering challenges across demanding industries. Each project reflects our commitment to practical, compliant, and experience-led solutions that deliver real value to our clients. These case studies provide a brief insight into the types of support we offer—from procedure development and compliance assurance to bespoke documentation and ongoing coordination services.

Our approach is grounded in technical expertise, clear communication, and a strong understanding of the standards that govern modern fabrication. Whether developing new welding procedures, resolving complex weld issues, enhancing quality systems, or creating tailored documentation, we focus on providing solutions that strengthen weld quality, improve reliability, and maintain full compliance.

Below are a selection of examples that demonstrate how our support has helped clients streamline their processes, reduce risk, and achieve consistent, high-quality results.

Super Duplex Weld Procedure Development

A marine client required the development of a fully compliant weld procedure for super duplex stainless steel (UNS S32760) — a material with strict metallurgical and mechanical requirements. We prepared a detailed pWPS, coordinated all Notified Body involvement, and created a comprehensive testing matrix covering both destructive and non-destructive examination across multiple codes.

Following successful testing, a complete and traceable WPQR package was compiled, including the final WPS and supporting welder qualification certification. The resulting procedure provided a robust, code-compliant solution suitable for demanding offshore service conditions.

Aluminium 6082 Marine Application

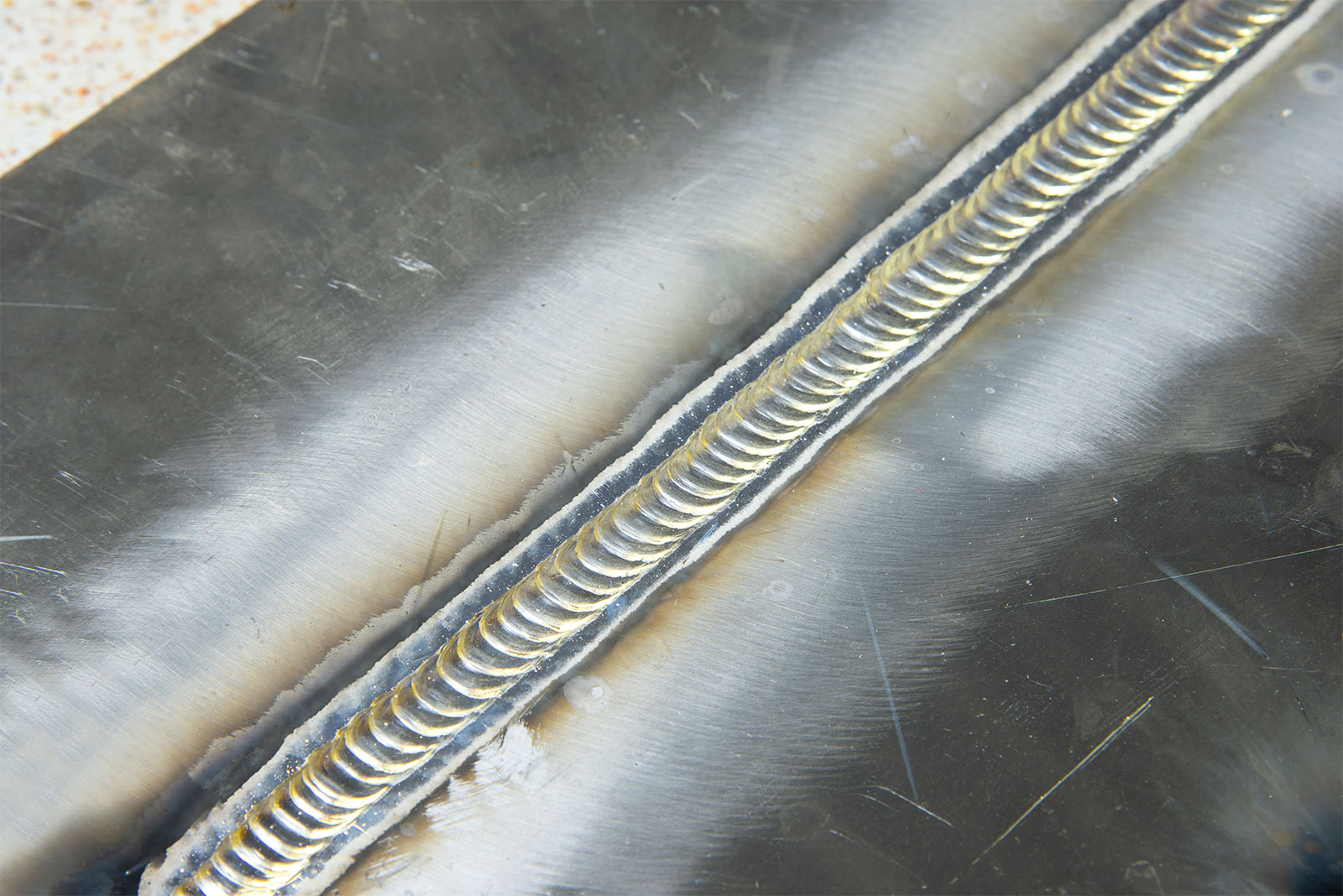

A marine project required a welding procedure for EN AW-6082 aluminium, a heat-treatable alloy prone to heat-affected zone (HAZ) strength loss if heat input are interpass temperatures are not carefully controlled. Triple Arc developed a bespoke pWPS designed to limit thermal degradation while maintaining structural integrity and productivity.

The procedure specified a pulsed MIG (GMAW-P) process with a carefully selected filler metal to balance strength, ductility, and corrosion resistance. Tightly controlled welding parameters and defined interpass temperature limits were implemented to minimise heat input and restrict HAZ width. The resulting procedure delivered a controlled, repeatable welding solution suitable for marine fabrication and compliant with applicable standards.

S690QL1 High-Strength Steel

A structural fabrication project involving S690QL1 required careful planning to ensure welding activities did not compromise the material’s high-strength, quenched and tempered condition. The key challenge was managing thermal input and execution control to maintain mechanical performance while allowing practical fabrication.

Rather than focusing solely on procedure qualification, Triple Arc developed a welding strategy that defined acceptable heat input limits, welding sequences, and execution controls suitable for highly restrained joints. Clear guidance was provided on parameter control, interpass temperature limits, joint preparation, and pass placement to manage thermal cycles and residual stresses during welding.

This approach gave the fabrication team a clear, controlled framework for welding S690QL1 components, reducing execution risk and ensuring consistent results. The final outcome was a practical, code-compliant welding solution that balanced structural performance with fabrication efficiency.

Visual Inspection Procedure

A structural fabrication client needed a consistent, standardised approach to visual inspection to maintain compliance with EN 1090-2. We developed a full visual inspection procedure in accordance with ISO 17637, providing clear acceptance criteria, inspection steps, and documentation requirements.

To support repeatability, we also created a tailored visual inspection report template that allowed the client’s inspectors to record findings consistently and in line with their quality management system. This improved traceability, reduced ambiguity, and strengthened their overall compliance position.

Responsible Welding Coordinator (RWC) Services

We provide continuing RWC support for clients operating in marine, structural, and general engineering sectors. This includes oversight of welding quality requirements in accordance with EN 1090-2, EN 15085 CL1, and EN ISO 3834-2, development of welding documentation, review of WPS/WPQR packages, and ongoing technical guidance.

Our continued involvement ensures each client maintains a compliant welding system and upholds the standards required within their certification scope.

Bespoke Weld Quality Guidebook

A client required a clear and reliable way to improve weld quality across their fabrication team. Their existing processes relied heavily on informal knowledge transfer, which led to inconsistent practices, variable weld quality, and gaps in understanding among new personnel.

To address this, we created a fully bespoke weld quality guidebook, tailored to the client’s materials, processes, and operational environment. The guidebook covers the fundamentals of weld quality, the importance of adherence to WPSs, sound engineering practices, typical weld defects and their prevention, and practical expectations for shop-floor welders. It also includes material-specific guidance, explaining how different alloys react during welding and what precautions are required to avoid defects and maintain mechanical integrity.

The final document provides the client with a structured, easy-to-follow reference tool that supports training, promotes consistent workmanship, and sets clear expectations for welding standards within their organisation.

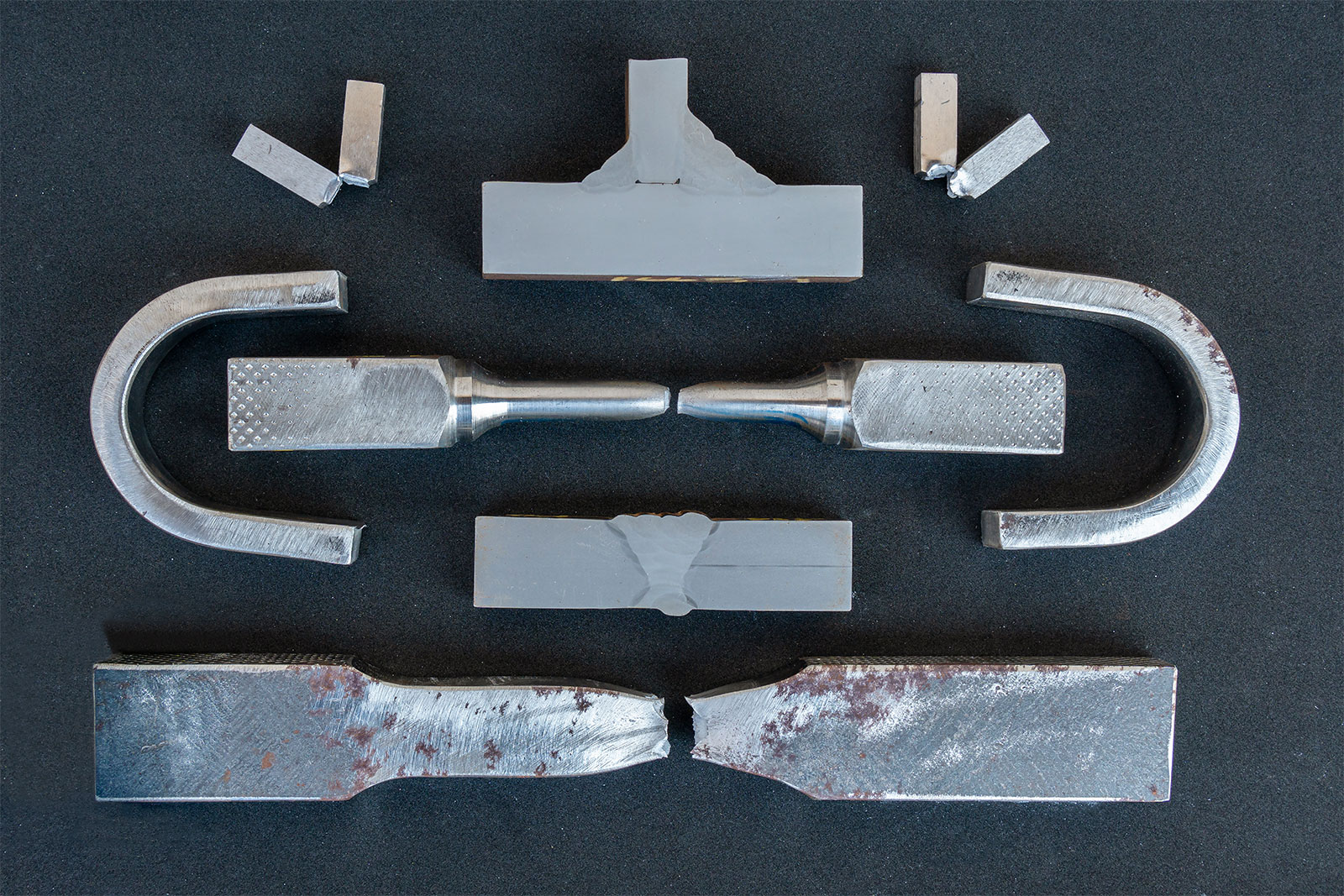

Customised Weld Repair Procedure

Another project required a formalised weld repair procedure to ensure welding defects were handled consistently and in compliance with relevant standards. Prior to this, repairs were carried out based on individual experience, which resulted in variable repair quality and difficulties with traceability.

We developed a comprehensive weld repair procedure tailored to the client’s operations. The document outlines the full repair workflow, including defect categorisation, preparation of the repair area, suitable excavation methods, acceptable repair techniques, and the correct use of non-destructive testing. It also clarifies the responsibilities of welding personnel, inspectors, and coordinators, ensuring that every repair is carried out using qualified staff and verified appropriately. Clear guidance on equipment, techniques, and post-repair evaluation helps standardise the process and minimise the risk of repeat defects.

This customised procedure now serves as a controlled, repeatable approach for managing weld repairs, improving quality consistency, reducing rework, and strengthening overall compliance